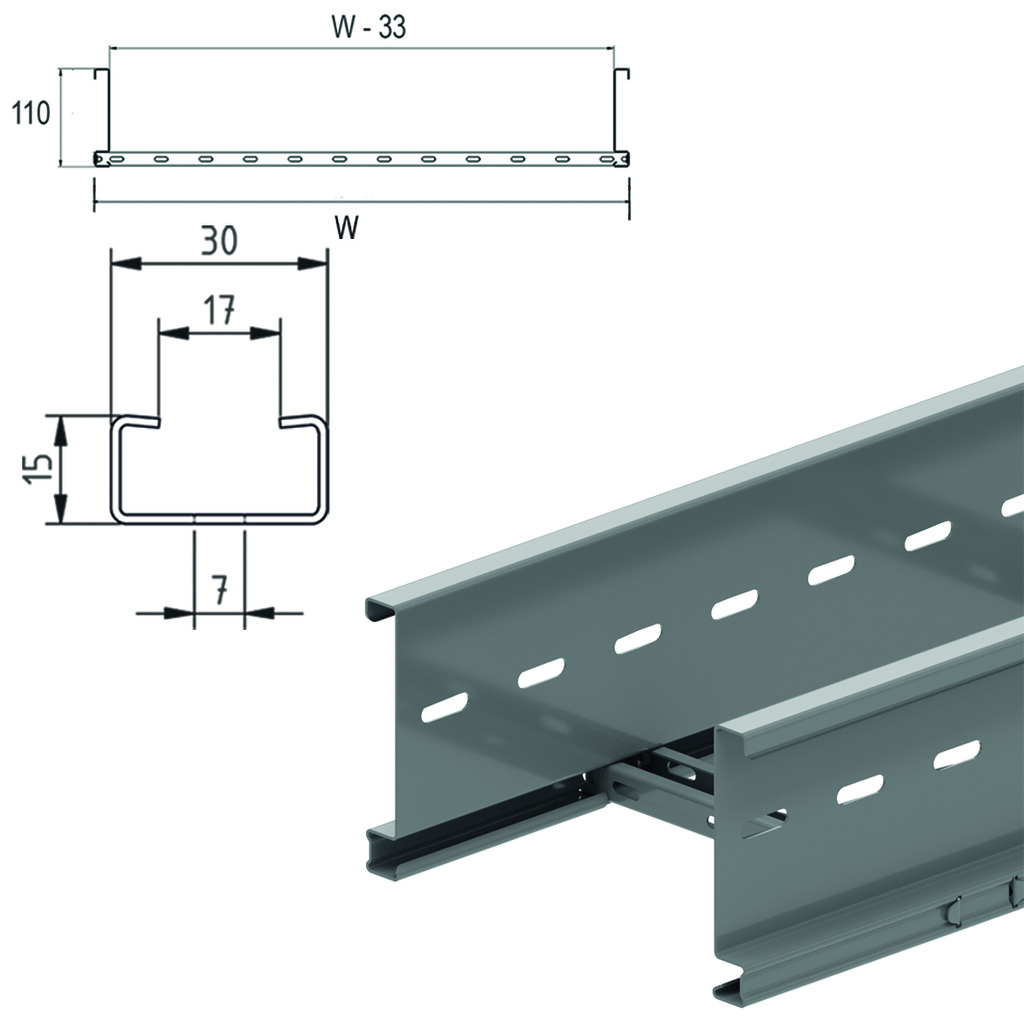

Cable ladder - KLL110

Side walls: perforated S-profile

Perforated C rungs 15x30

Usable inner height: 94 mm

Rung distance: 250 mm

ETIM: EC000854

Perforated C rungs 15x30

Usable inner height: 94 mm

Rung distance: 250 mm

ETIM: EC000854

| Reference |

mm |

mm |

mm |

mm |

kg m |

Unit | |

| KLL110.150 | 110 | 150 | 1.25 | 3000 | 3.570 | 18 | M |

| KLL110.200 | 110 | 200 | 1.25 | 3000 | 3.687 | 18 | M |

| KLL110.300 | 110 | 300 | 1.25 | 3000 | 3.921 | 18 | M |

| KLL110.400 | 110 | 400 | 1.25 | 3000 | 4.155 | 18 | M |

| KLL110.450 | 110 | 450 | 1.25 | 3000 | 4.272 | 18 | M |

| KLL110.500 | 110 | 500 | 1.25 | 3000 | 4.389 | 18 | M |

| KLL110.600 | 110 | 600 | 1.25 | 3000 | 4.623 | 18 | M |

| KLL110.750 | 110 | 750 | 1.25 | 3000 | 4.975 | 18 | M |

| KLL110.800 | 110 | 800 | 1,25 | 3000 | 5.092 | 18 | M |

| KLL110.900 | 110 | 900 | 1.25 | 3000 | 5.326 | 18 | M |

| ZMKLL110.150 | 110 | 150 | 1.25 | 3000 | 3.570 | 18 | M |

| ZMKLL110.200 | 110 | 200 | 1.25 | 3000 | 3.687 | 18 | M |

| ZMKLL110.300 | 110 | 300 | 1.25 | 3000 | 3.921 | 18 | M |

| ZMKLL110.400 | 110 | 400 | 1.25 | 3000 | 4.155 | 18 | M |

| ZMKLL110.450 | 110 | 450 | 1.25 | 3000 | 4.272 | 18 | M |

| ZMKLL110.500 | 110 | 500 | 1.25 | 3000 | 4.389 | 18 | M |

| ZMKLL110.600 | 110 | 600 | 1.25 | 3000 | 4.623 | 18 | M |

| ZMKLL110.750 | 110 | 750 | 1.25 | 3000 | 4.975 | 18 | M |

| ZMKLL110.800 | 110 | 800 | 1.25 | 3000 | 5.092 | 18 | M |

| ZMKLL110.900 | 110 | 900 | 1.25 | 3000 | 5.326 | 18 | M |