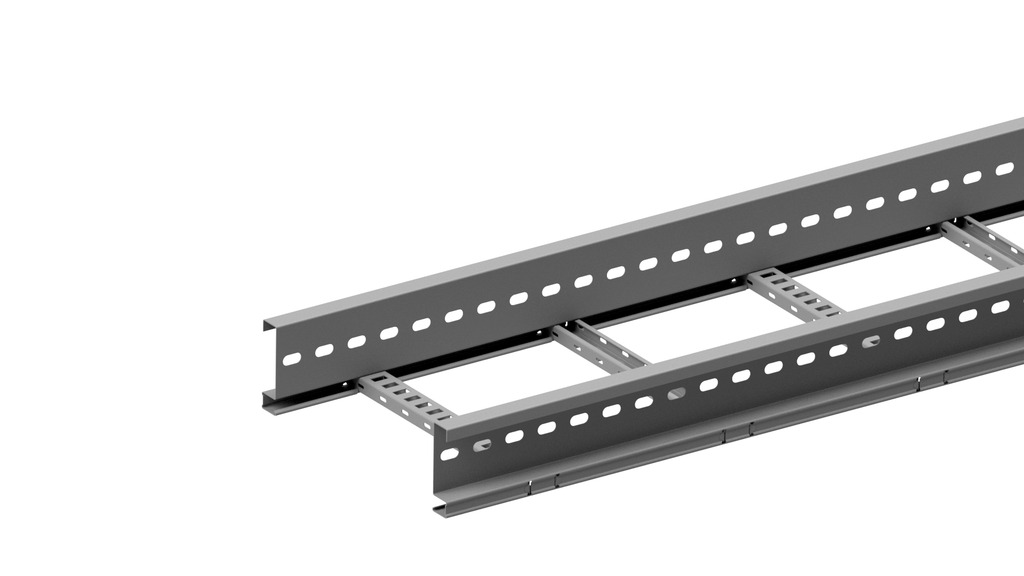

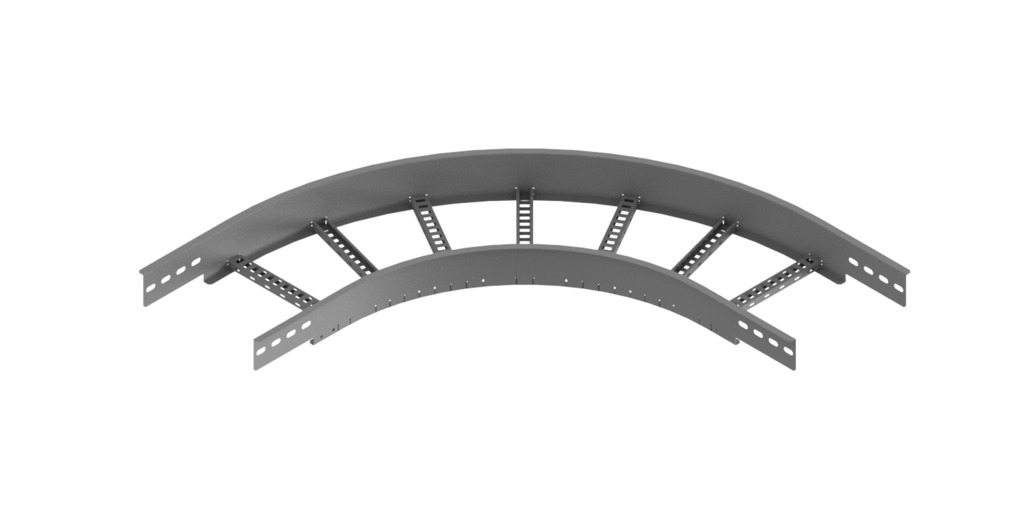

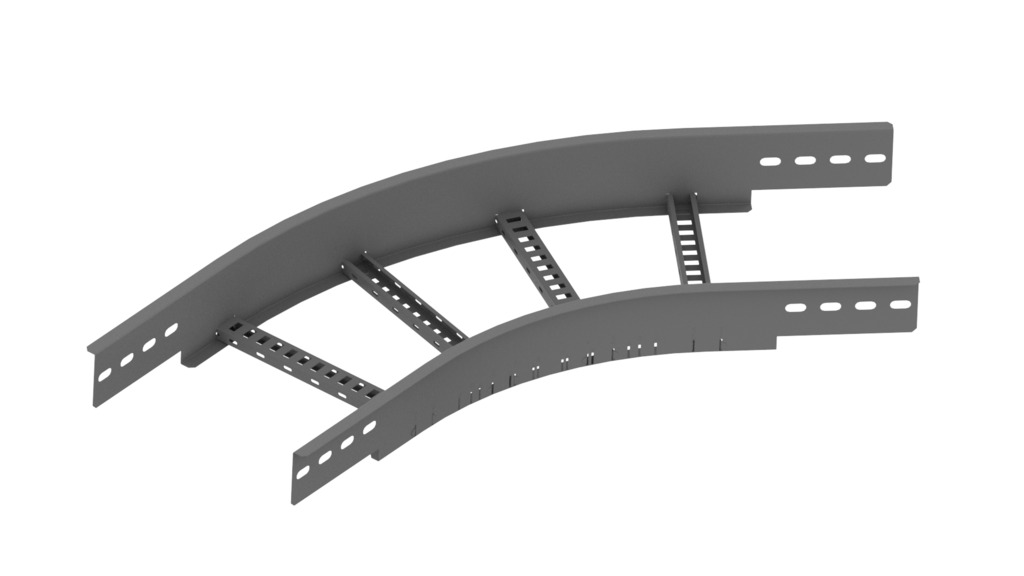

Cable ladder height 125 - KLM125.3

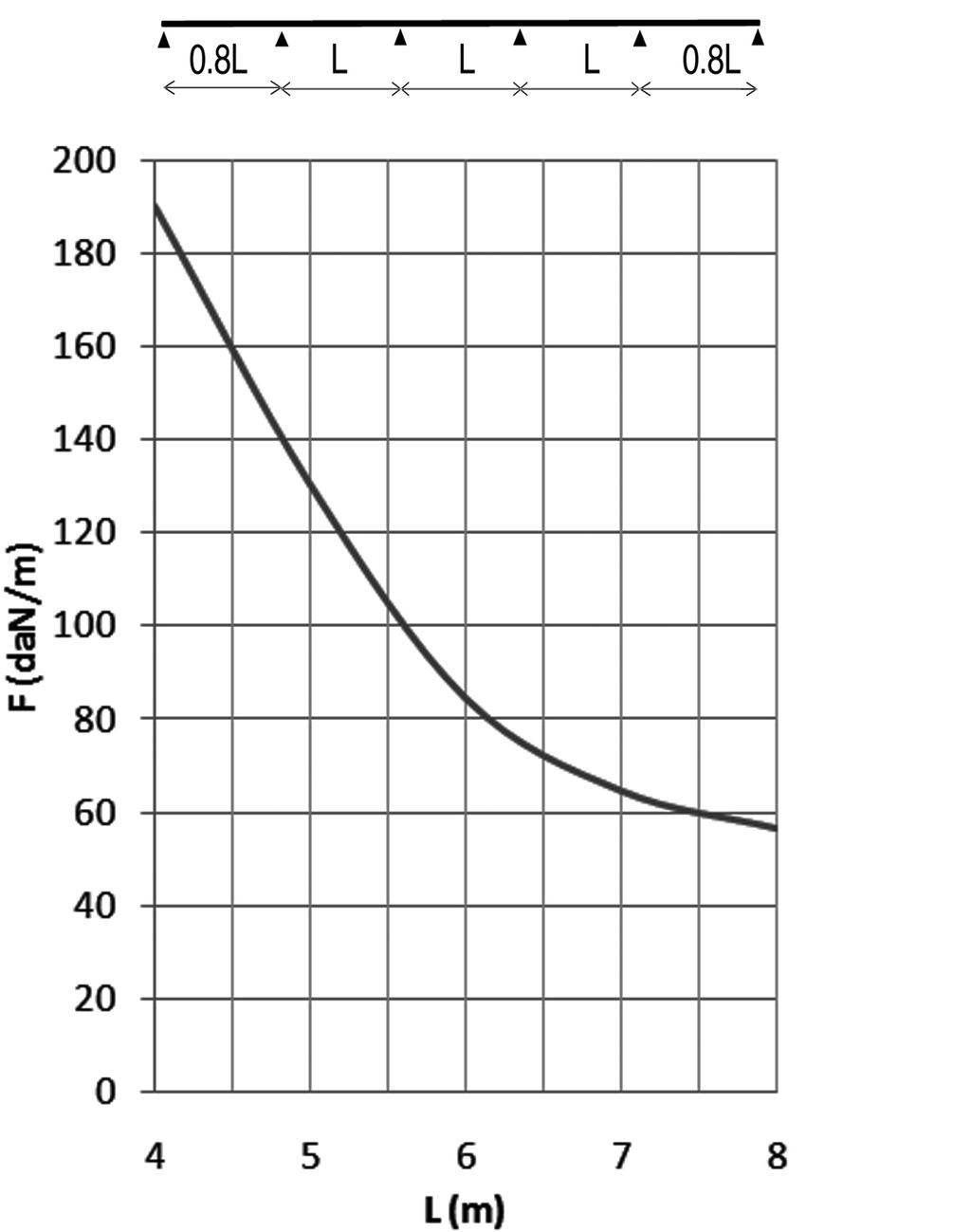

Cable ladder for large support distances up to 8 metres

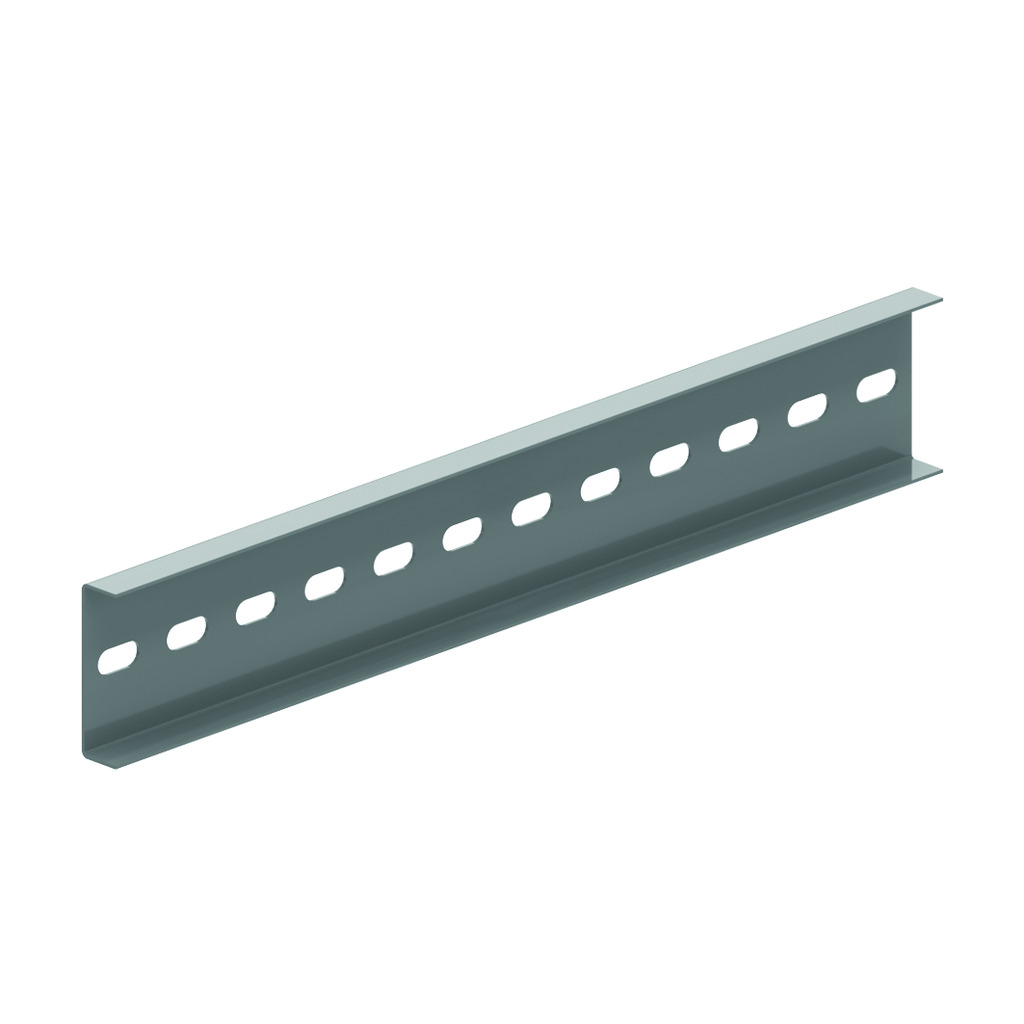

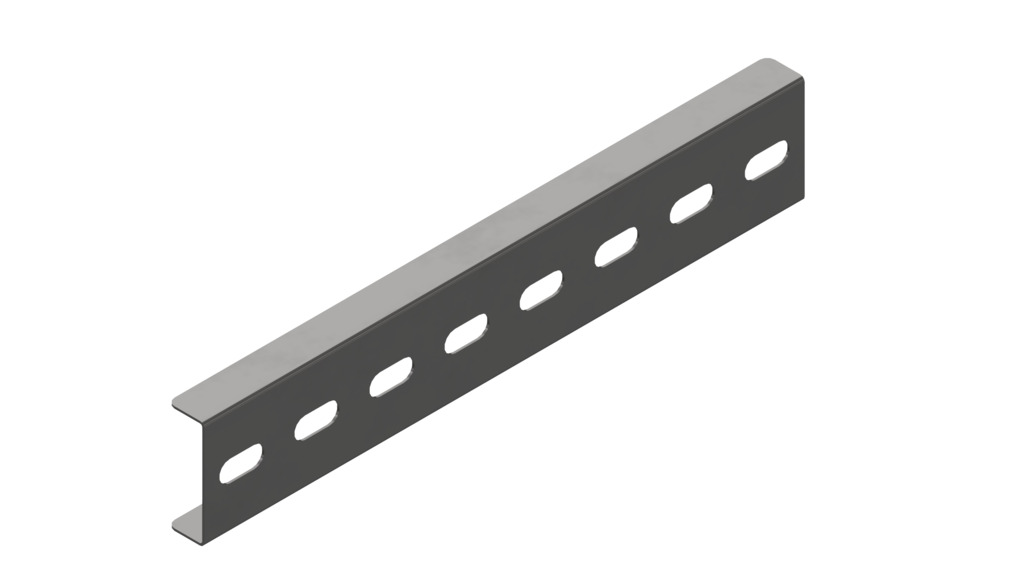

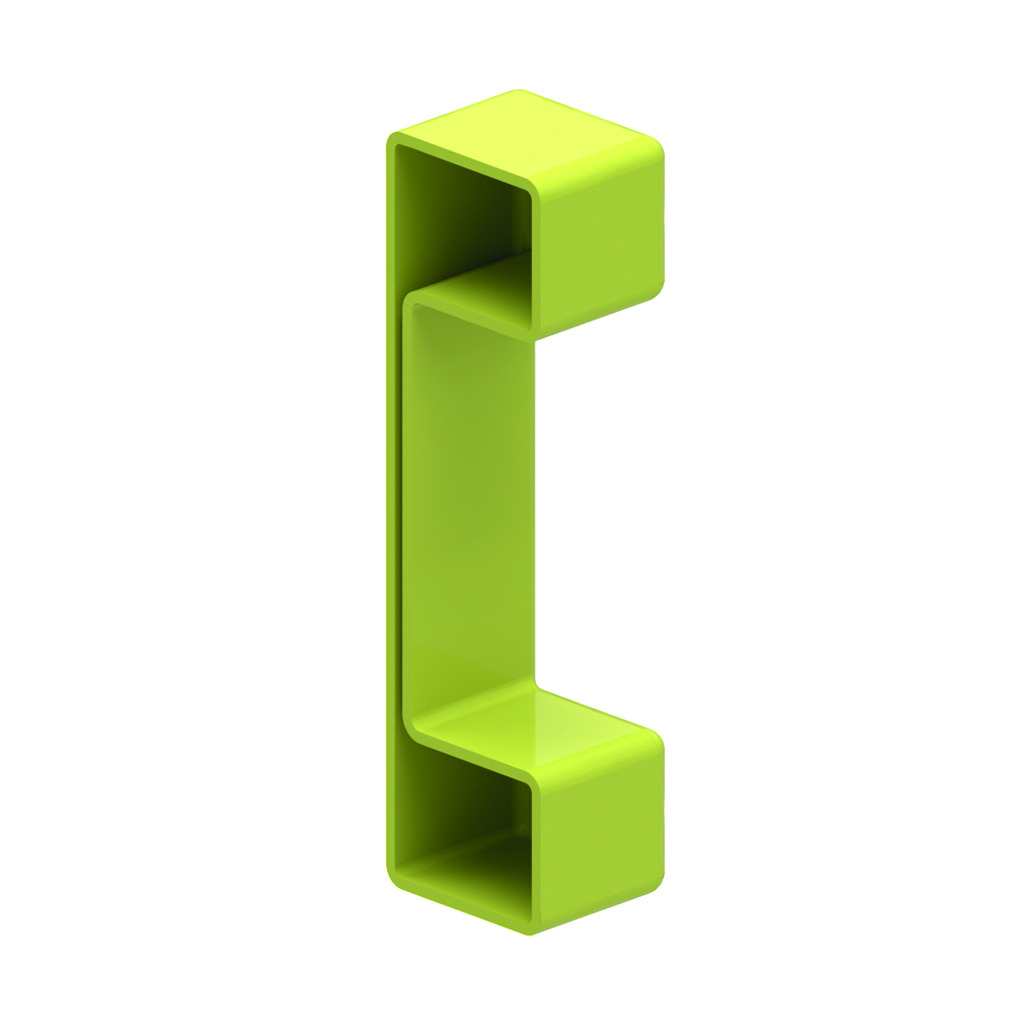

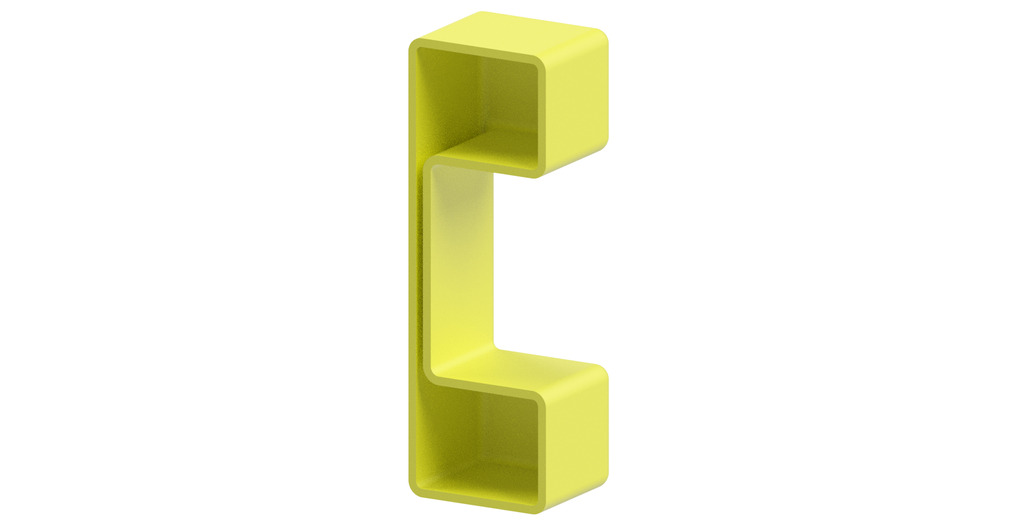

Perforated C datarungs 41x21

Usable inner height: 102 mm

Rung distance: 300 mm

To order: Length 6000 mm

To order: Width 700 - 1200 mm (increments of 100 mm)

ETIM: EC000854

Perforated C datarungs 41x21

Usable inner height: 102 mm

Rung distance: 300 mm

To order: Length 6000 mm

To order: Width 700 - 1200 mm (increments of 100 mm)

ETIM: EC000854

| Reference | Finish |

mm |

mm |

mm |

mm |

kg m |

Stock | Unit | |

| KLM125.150.3 | ZP | 125 | 168 | 1.5 | 3000 | 5.723 | 48 | M | |

| KLM125.200.3 | ZP | 125 | 218 | 1.5 | 3000 | 5.851 | 48 | M | |

| KLM125.300.3 | ZP | 125 | 318 | 1.5 | 3000 | 6.111 | 48 | M | |

| KLM125.400.3 | ZP | 125 | 418 | 1.5 | 3000 | 6.363 | 48 | M | |

| KLM125.450.3 | ZP | 125 | 468 | 1.5 | 3000 | 6.491 | 48 | M | |

| KLM125.500.3 | ZP | 125 | 518 | 1.5 | 3000 | 6.619 | 48 | M | |

| KLM125.600.3 | ZP | 125 | 618 | 1.5 | 3000 | 6.875 | 48 | M | |

| KLM125.750.3 | ZP | 125 | 768 | 1.5 | 3000 | 7.259 | 48 | M | |

| KLM125.800.3 | ZP | 125 | 818 | 1.5 | 3000 | 7.387 | 48 | M | |

| KLM125.900.3 | ZP | 125 | 918 | 1.5 | 3000 | 7.644 | 48 | M | |

| KLM125.1000.3 | ZP | 125 | 1018 | 1.5 | 3000 | 7.900 | 48 | M |